Small CNC milling machines can also be used for scientific research experiments, providing precise machining tools for researchers. In addition, it can also serve as a platform for competitions and exhibitions.

Small CNC milling machines can also be used for scientific research experiments, providing precise machining tools for researchers. In addition, it can also serve as a platform for competitions and exhibitions.

With the rapid development of the manufacturing industry, the demand for talents in CNC machining center technology is also increasing. Learning to use CNC machining centers is of great significance for personal skill enhancement, manufacturing industry development, and employment prospects.

Machining centers are widely used in fields such as mechanical manufacturing, aerospace, automobile manufacturing, mold making, and medical equipment manufacturing.

The small CNC milling machine has become an indispensable tool in modern manufacturing and education due to its high precision, high efficiency, high stability, and wide range of application scenarios.

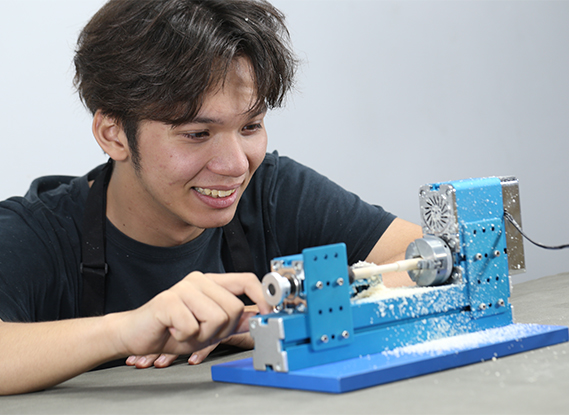

Small CNC milling machine is a high-precision automated processing equipment widely used in various mechanical processing fields. A small CNC milling machine is a milling machine with a relatively small volume and compact structure. It integrates a digital control system and can perform milling processing more accurately under the control of program code.

XENDOLL small CNC milling machine is compact in size and occupies a small area, making it suitable for use in places with limited space. Meanwhile, its compact structure and easy operation make small CNC milling machines more flexible in processing small and complex shaped parts. This advantage makes small CNC milling machines widely used in industries such as mechanical processing and mold manufacturing.

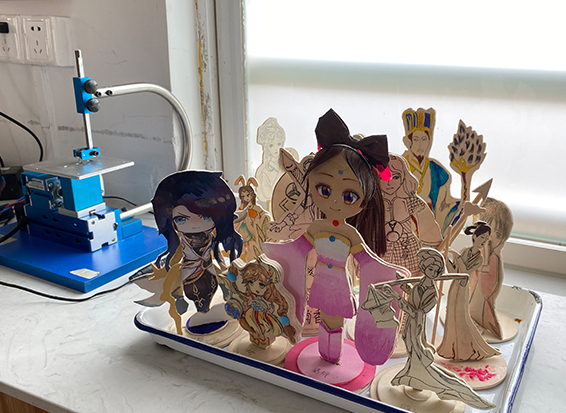

The introduction of small CNC milling machines has promoted the modernization process of educational equipment. As one of the advanced educational equipment, it has the characteristics of high precision, high efficiency, and multifunctionality, which can meet the demand for technical talents in modern manufacturing industry.

Interesting free disassembly and assembly, meeting the needs of design users, all parts of the machine are made of metal, improving equipment utilization, and reasonable precision control design, condensing the essence of industrial design.

A small five axis machining center can automatically and continuously complete multiple machining processes for multiple planes, achieving efficient and high-quality machining.

Industrial Intelligence is a comprehensive major that involves multiple fields such as machinery, electronics, and computer science. It mainly studies the technologies, applications, and development related to industrial intelligent manufacturing.

Allowing students to easily master the loading and unloading of industrial 6-axis robots and the construction of flexible machining production systems using CNC machines can meet their needs for learning and operating industrial robots. Through the learning and training of this system, students have a comprehensive understanding and experience of the overall application of intelligent production unmanned factories.

By participating in specific technical projects or practical activities, such as woodworking, metalworking, and other handmade projects, students' hands-on ability and innovative thinking are cultivated through these activities, and technical knowledge is learned and mastered through practice.