Laser engraving machine is a kind of mechanical equipment that is currently engaged in processing and production, and is widely used in products related to people's daily life. In various skills, makers, innovation competitions and daily teaching activities in primary and secondary schools and vocational colleges, laser engraving machines have become the best choice for production equipment due to their excellent performance.

The pilot laser engraving machine has three specifications, which can be selected according to different needs.

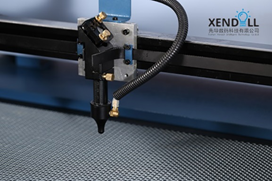

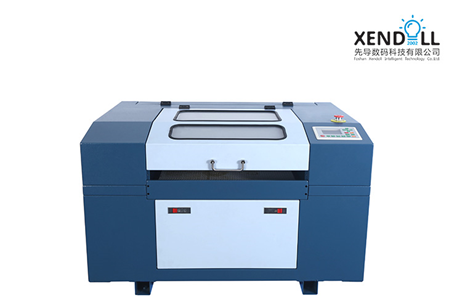

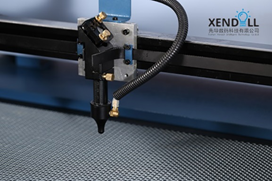

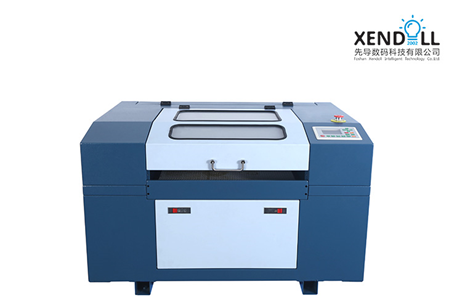

Laser engraving machine 9060 (laser power 60-100W optional): strong power, efficient cutting, dimensions: total weight: suitable for woodworking, campus makers, technology production, general technical teaching in high schools, etc.

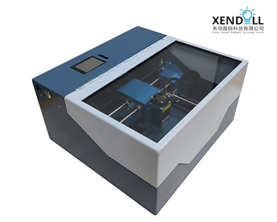

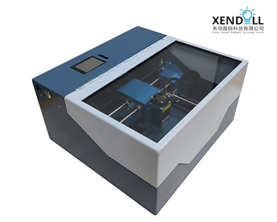

Desktop laser engraving machine 6040 (laser power 40-50W): can be placed directly on the desktop, easy to move, dimensions: total weight: suitable for woodworking, campus makers, technology production, high school general technical teaching, etc.

Micro laser engraving machine XD1213 (laser power 2.5W), small and portable, can be used for engraving stamps and DIY personal special items, it is a good learning partner for beginners. Dimensions: total weight: suitable for primary and secondary school students to practice in woodworking, maker, technology production and other scenes

The salient features of the leading laser engraving machine:

1. Wide range of materials: CO2 lasers can engrave and cut almost any non-metallic material

2. Safe and reliable: Non-contact processing will not cause mechanical extrusion or mechanical stress to the material. No "knife marks", no damage to the surface of the workpiece; no deformation of the material;

3. Easy to use: High-speed engraving and cutting can be performed immediately according to the pattern output by the computer.

4. Saving and environmental protection: the diameter of the beam and the spot is small, generally less than 0.5mm; the cutting process saves materials and is safe and hygienic;

5. Efficient and fast: ensure the same processing effect of the same batch without post-processing.