Add Date: 2025/12/9 Views: 40

# Small CNC Machine Tool, # Desktop CNC Machine Tool, # Small Teaching CNC Milling Machine, # Small Teaching Machining Center, # Desktop CNC Lathe

In the era of "small yet sophisticated" manufacturing, innovation no longer relies on large-scale equipment and high costs. Whether it’s a startup team refining their first product prototype, a university laboratory conducting engineering training, or a precision processing factory undertaking high-demand small-batch orders, a high-performance small CNC milling machine has become a core tool to turn ideas into reality and accelerate R&D iteration. It not only makes complex processes accessible, but also redefines the possibilities of desktop-level manufacturing with its compact size, intelligent operation, and outstanding precision.

Small CNC milling machines boast multiple significant advantages in small part processing and sample production, making them particularly suitable for scientific research institutions, university laboratories, maker spaces, small processing factories, and enterprises in the initial stage of product development.

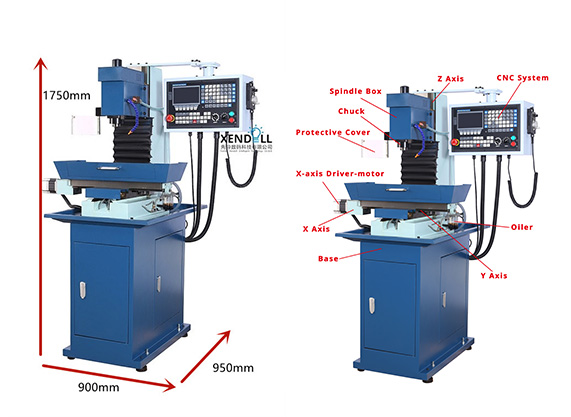

Small CNC Milling Machine, Model: C31

Technical Parameters

Maximum Drilling Diameter: 13mm

Maximum Tool Locking Diameter: 16mm

Maximum Milling Diameter: 50mm

Worktable Size: 450×160mm

X-axis Travel: 300mm

Y-axis Travel: 175mm

Z-axis Travel: 270mm

Spindle Speed Range: 300-3500 rpm

Rapid Traverse Speed: 6000mm/min

Spindle Motor Power: 1.1KW

Gross Weight: 350KG

Machine Dimensions: 900×950×1750mm

Modern small CNC milling machines are usually equipped with user-friendly control systems, resulting in a low learning threshold.The small worktable and travel of such equipment are suitable for processing small-sized parts, reducing raw material waste.Compared with large CNC machine tools, they have lower purchase costs, floor space requirements, and energy consumption, thus lowering initial investment and operational costs.Small CNC milling machines generally feature high positioning accuracy (up to ±0.01 mm or even higher), which can meet the processing requirements of precision small parts.The CNC system ensures the consistency of each processing operation, making it ideal for batch trial production or small-batch production.

Choosing a reliable small CNC milling machine is not just selecting a processing tool, but opting for an efficient, flexible, and future-oriented manufacturing method. Whether you are an engineer, educator, maker, or small and medium-sized enterprise owner, it can serve as the most trustworthy bridge from your concept to the finished product. Let manufacturing no longer be out of reach—small body, great achievements, and start your new chapter of intelligent manufacturing from now on.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll

WEB:www.xendolltools.com