Add Date: 2025/6/17 Views: 1

Keyword:Small machining center, Desktop machining center,Small five axis machining center, Desktop teaching machining center, Pilot five axis linkage machining center

Is an extraordinary creation lingering in your mind? Perhaps it has the intricate form of an artwork, with curves flowing as if shaped by nature. Maybe it features exquisitely complex structures demanding micron-level precision. Or perhaps it requires machining every feature in a single setup, pursuing ultimate efficiency and perfection.

When traditional machining methods fall short of your vision, the 5-axis machining center becomes the essential key to transform your blueprint into a tangible masterpiece.

Achieving "Efficient" One-Stop Intelligent Manufacturing & the "Single Setup Revolution" for Complex Parts: Say goodbye to cumbersome repositioning and fixture changes. A 5-axis machining center allows you to machine five surfaces in a single setup, drastically shortening production cycles, minimizing accumulated error, and significantly boosting yield rates.

The Ideal Partner for Low-Volume, High-Value-Added Products: Whether it's custom prototype verification, small-batch trial production, or flexible manufacturing of high-value components, 5-axis machining delivers unparalleled flexibility, speed, and precision assurance.

Optimize Processes, Reduce Costs, Increase Efficiency: Reduce machining steps, simplify fixturing, and shorten lead times. 5-axis technology not only elevates product quality but also effectively optimizes your overall manufacturing cost structure.

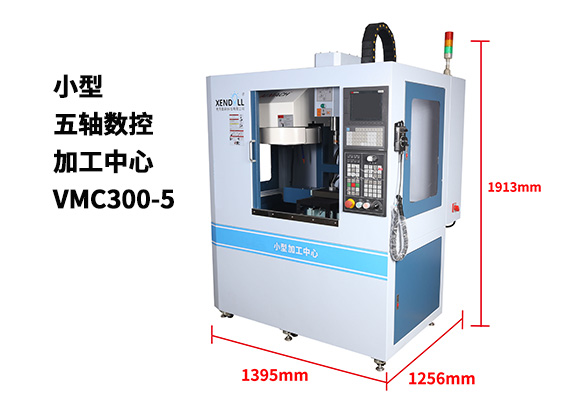

If cost or space constraints are a factor, consider a compact 5-axis machining center as your solution.

VMC300-5

|

Positioning Accuracy |

±0.015mm |

|

Repeat Positioning Accuracy |

±0.01mm |

|

Tool Clamping |

2-13mm |

|

Work Table |

550mm*160mm |

|

X-axis Travel |

300mm |

|

Y-axis Travel |

175mm |

|

Z-axis Travel |

270mm |

|

B-axis Travel |

0-100° |

|

C-axis Travel |

360° |

|

Spindle Speed |

300-24000rmp |

|

Spindle Motor Power |

1.5KW |

|

Feed Control |

Equipped with Servo Motors |

|

Rapid Traverse Rate |

10000mm/min |

|

Tool Magazine Capacity |

12-Tools |

|

Automatic Tool Changer Type |

Pneumatic Tool Changer System |

|

Power |

AC380V/50Hz |

|

Size |

1360×1080×1830mm |

|

Weight |

670KG |

Choosing a 5-axis machining center means choosing:

Boundless Possibility to Transform Vision into Reality: Break free from geometric constraints and let your design inspiration run wild.

Uncompromising Quality Standards for Your Work: Enhance manufacturing competitiveness, shorten delivery cycles, increase responsiveness, and seize market opportunities.

Mastery of Cutting-Edge Manufacturing Capabilities: Establish your leadership position in the high-end manufacturing sector.

Our advanced 5-axis machining center solutions, equipped with state-of-the-art CNC systems, high-performance spindles, and robust mechanical structures, are complemented by our deep industry expertise and dedicated technical support. They provide the solid foundation you need to:

Tame Complexity: Confidently tackle the most intricate challenges.

Pursue Perfection: Achieve the highest levels of precision and finish.

Drive Efficient, Intelligent Manufacturing: Optimize your production processes.

Realize Your Extraordinary Creation: Bring that exceptional masterpiece in your mind to life.

Stop letting process limitations constrain your imagination. Let the 5-axis machining center be your launching pad for forging the exceptional.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll

WEB:www.xendolltools.com